Conductive pressure-sensitive adhesive is a special type of adhesive that conducts electricity under applied pressure, while maintaining an insulating state in the absence of pressure. Its main characteristics include adjustable resistivity, pressure-sensitive adhesion, and stability. These properties make it widely applicable in the manufacturing of touch screens, pressure sensors, electronic components, and other related areas.

Schematic Diagram of the Application of Conductive Pressure-Sensitive Adhesive:

To meet various application requirements, conductive pressure-sensitive adhesives need to possess the following properties:

1. Conductive Performance: One of the main characteristics of conductive pressure-sensitive adhesives is their excellent conductive performance. They can provide a stable electrical conduction path, facilitating effective current transmission in electronic components.

2. Pressure-Sensitive Performance: Conductive pressure-sensitive adhesives also exhibit pressure-sensitive performance, meaning they can alter their resistance values based on changes in pressure or strain. This pressure-sensitive characteristic finds widespread application in areas such as pressure sensors, touchscreens, and flexible circuit boards.

3. Good Bonding Performance: Conductive pressure-sensitive adhesives have strong bonding capabilities, securely adhering to different material surfaces and providing stable connections. They can maintain consistent bonding performance under varying temperature, humidity, and environmental conditions.

4. Corrosion Resistance: Conductive pressure-sensitive adhesives typically possess good corrosion resistance, enabling them to maintain their conductive and pressure-sensitive properties for extended periods in harsh environments. This durability and reliability make them more suitable for various industrial applications.

5. Processability: Conductive pressure-sensitive adhesives are easy to process and shape, allowing for cutting, rolling, and molding according to specific requirements. This processability makes them suitable for applications of different shapes and sizes.

Nickel powder

Nickel powder is a common conductive filler, characterized by excellent conductivity and stable physical and chemical properties.

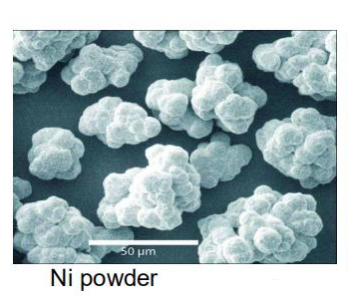

SEM image of nickel powder:

Nickel powder in conductive pressure-sensitive adhesives primarily serves to enhance conductivity and optimize pressure-sensitive adhesion.

1. Enhancing Conductivity

By incorporating nickel powder, the resistivity of the conductive pressure-sensitive adhesive can be reduced, enabling it to maintain a certain level of conductivity even in the absence of pressure.

2. Optimizing Pressure-Sensitive Adhesion

A proper amount of nickel powder can enhance the adhesion between the conductive pressure-sensitive adhesive and the substrate, reducing the likelihood of detachment during use.

3. Impact on Durability

Nickel powder possesses high chemical stability, contributing to improved durability of the conductive pressure-sensitive adhesive. This stability helps maintain consistent performance over extended periods of use.

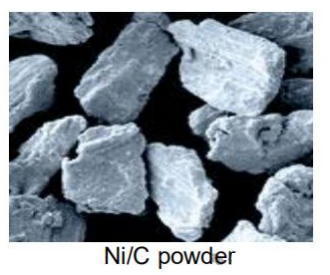

Nickel-coated graphite

SEM image of nickel powder:

Nickel-coated graphite combines the high conductivity of nickel powder with the pressure-sensitive properties of graphite, offering an excellent material choice for various applications requiring adhesion and conductivity.

1. Conductivity

As a conductive filler, nickel-coated graphite plays a crucial role in conductive pressure-sensitive adhesives. Due to graphite's inherent conductivity, coupled with the composite structure involving nickel, its conductivity is further enhanced. This conductivity allows the conductive pressure-sensitive adhesive to form a reliable current path under applied pressure, exhibiting excellent conductivity in practical applications.

2. Pressure-Sensitivity

In conductive pressure-sensitive adhesives, nickel-coated graphite not only provides conductivity but also enhances the adhesive's pressure-sensitive properties. The composite structure of graphite and nickel makes the adhesive more sensitive to pressure, leading to a rapid response and the generation of adhesive forces.

Our recommendations for the use of conductive fillers based on adhesive layer thickness:

☆ For conductive pressure-sensitive adhesives with fabric backing, it is recommended to use particle sizes slightly larger than the adhesive layer thickness (35 micrometers), such as 40 or 50 micrometers.

☆ For conductive pressure-sensitive adhesives with metal backing, it is recommended to use particle sizes identical to the adhesive layer thickness (35 micrometers).

Conductive Filler Compatibility Table for Oerlicon (All below are Oerlicon product grades):

| Adhesive thickness | Suitable conductive filler |

| 20μm | #2708 or #2707 |

| 30μm | # 1231, #2708 or #2806 |

| 35μm | #2805, #1231 or #2806 |

| 40μm | #1231 or #2805 |

| 50μm | #2805 |

| 55μm | #2805 or #2801 |

| 75μm | #2801 or #2805 |

| 100μm | #2701 |

| >100μm | #2702 |

As a distributor of fine chemical products, We, Beijing Entrepreneur offers conductive fillers nickel powder and nickel-coated graphite from Oerlicon.

Copyright © 2023 Beijing Entrepreneur Science & Trading Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist