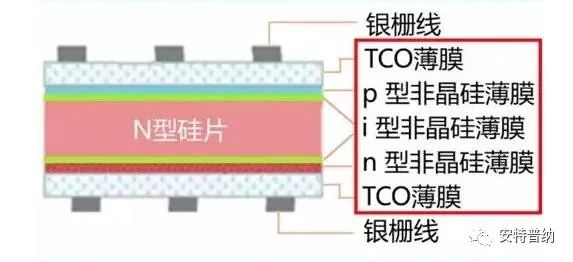

HJT cells, known as heterojunction cells with thin amorphous silicon films, consist of two different semiconductor materials forming a heterojunction. Heterojunction with intrinsic thin layer (HJT) solar cells involve depositing thin amorphous silicon films onto crystalline silicon. They combine the advantages of crystalline silicon and thin-film technology, offering high conversion efficiency, low processing temperatures, high stability, minimal degradation, and the ability to generate electricity from both sides. This technology is considered revolutionary.

The low-temperature silver paste used in HJT photovoltaic cells is created by mixing silver powder, resin, and other solvents in a relatively low-temperature environment of 200-250°C. Due to the specific properties of HJT cells, such as the high hydrogen content in the thin amorphous silicon film, the production process demands temperatures not exceeding 250°C. Hence, the low-temperature silver paste becomes a critical material in the manufacturing process.

The key to the low-temperature curing of silver paste lies in the performance of the silver powder. As the primary component of the low-temperature silver paste, silver powder possesses excellent conductivity and thermal conductivity. During low-temperature curing, the silver powder can uniformly mix with organic solvents, resin, and additives, playing a role in dissolving the resin during the curing process.

Specifically, the particle size, shape, and structure of the silver powder all affect its conductivity and thermal conductivity. To achieve better low-temperature curing effects, silver powder with high purity, density, small particle size, and spherical particles is generally chosen. Additionally, the surface treatment of silver powder is also a crucial factor influencing its performance.

Antepp Sodium Company collaborates with leading metal powder suppliers in the United States and domestically, providing stable raw material supply and professional technical support for the research and development of low-temperature conductive slurries for heterojunction HJT products.

AMES' sub-micron silver powder 18040-NM2.

The typical values of silver powder 18040-NM2 are:

SEM:

AMES' sub-micron silver powder 16-465.

The typical values of silver powder 16-465 are:

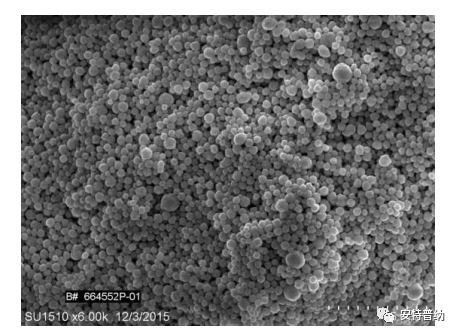

SEM:

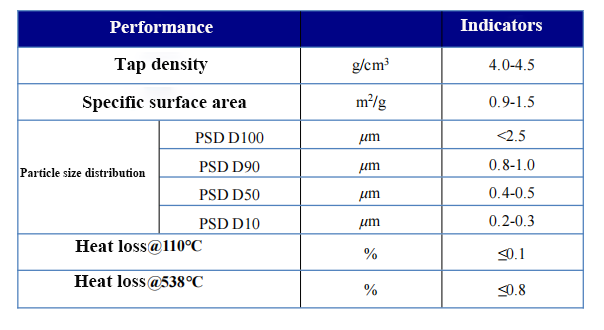

Domestically produced high-quality sub-micron silver powder ATPN024.

Product overview: High sphericity, excellent dispersibility, narrow particle size distribution (300nm), suitable for HJT and metal grid applications.

The performance indicators of ATPN024 are:

SEM:

Copyright © 2023 Beijing Entrepreneur Science & Trading Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist